Use Cases

The studies performed provide an essential contribution to the scientific community, supporting the reliability, performance, and long-term stability of systems operating under extreme conditions.

Advanced Materials & Processing:

We develop, characterize, and qualify structural and functional materials for accelerator and fusion technologies. Recent research focuses on cryogenic mechanical testing, surface engineering, development of low-Z materials, and superconducting solutions.

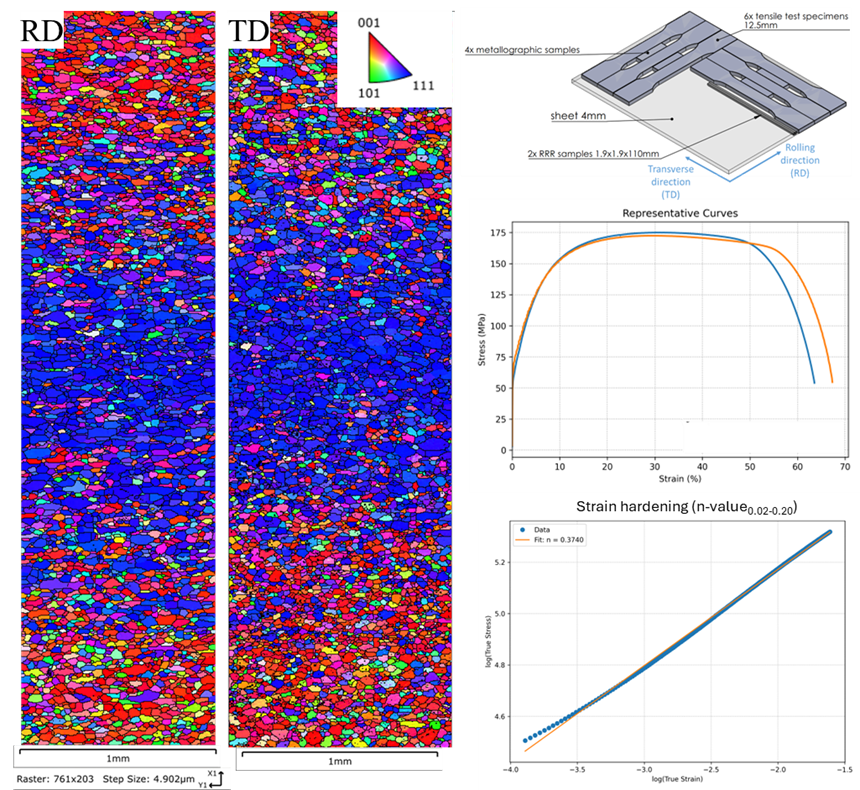

Niobium for the Future Circular Collider (FCC)

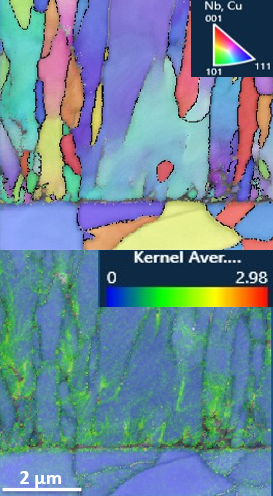

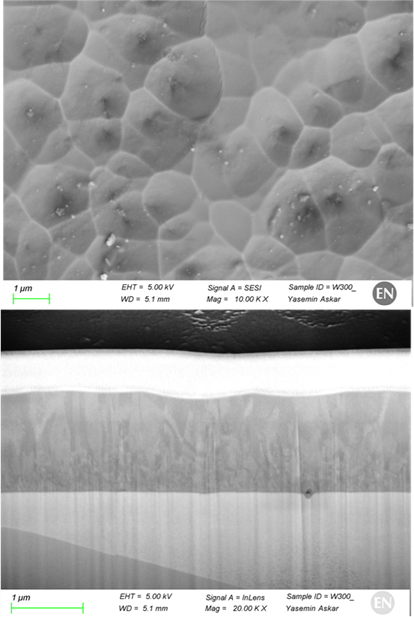

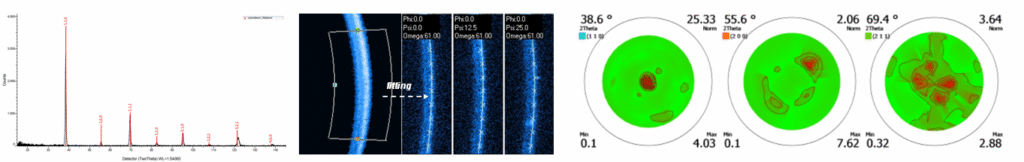

As part of the Future Circular Collider (FCC) study, EN-MME-MM is developing advanced niobium coatings for superconducting radio-frequency (SRF) cavities, key components operating below 2 K to maximize energy efficiency.

Using bipolar HiPIMS deposition and advanced characterization methods such as FIB, SEM, EBSD, and X-ray diffraction, researchers investigate film microstructure, texture, and residual stress.

This work supports the optimization of Nb thin films, enabling more cost-effective SRF technologies and contributing to the design of next-generation accelerators.

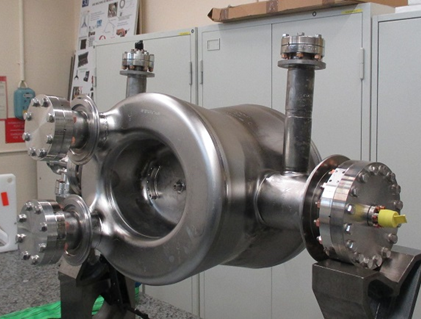

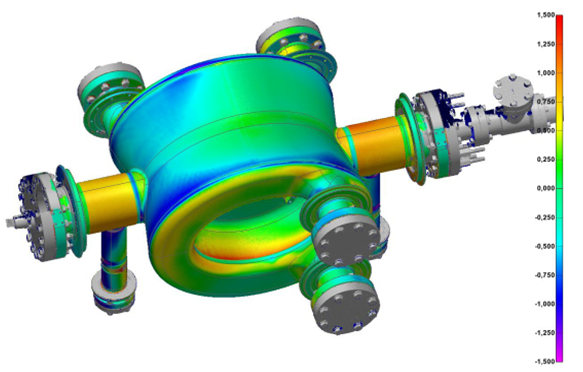

Support to the HL-LHC Crab Cavities manufacturing

The High-Luminosity LHC (HL-LHC) upgrade will boost the collider’s peak luminosity by a factor of five, requiring the integration of sixteen advanced “crab cavities” and their RF cryomodules at ATLAS and CMS.

Our group plays a key role in this effort the timely procurement and qualification of the superconducting material through detailed characterization and strict quality control before manufacturing.

During production, metrology and NDT experts perform dedicated inspections and validation measurements, ensuring that each component meets CERN’s technical and performance stan

Material Performance in Demanding Conditions:

Is our goal to better understand how components behave in the real operation conditions in the accelerator (radiation effects, vacuum properties, mechanical behaviour at high or low temperatures, fatigue, corrosion resistance, beam interaction…)

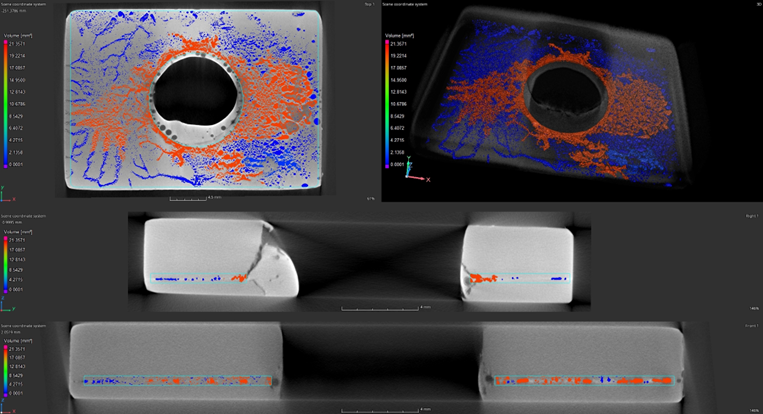

n-TOF Autopsy

After the 2018 operation of the n_TOF facility, features consistent with corrosion were observed on the lead target windows. Using remote and robot-assisted tools, the EN-MME-MM team performed visual and metrological inspections with 3D system to map surface changes, followed by microscopy and diffraction analyses on collected samples.

The investigation helped determine the origin of the observed features and will guide improvements in material compatibility and maintenance procedures for irradiated targets.

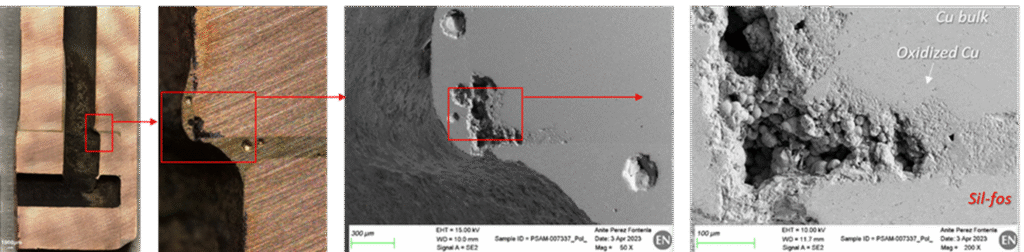

Corrosion behaviour of Brazed Water-Cooling Conducts in the PSB

Non-destructive testing and microscopic analysis of extracted samples from PSB cooling system revealed galvanic corrosion at the cuprous base material and braze interface. This triggered a systematic evaluation of brazed conducts on other parts of the accelerator complex relaying on Automated Particle Analysis (APA) of the corrosion residues circulating in the water in those points less accessible or where the sampling is not applicable.

Component Integrity and Failure analysis:

We provide in-depth evaluations of components integrity and material failures that help to avoid critical breakdowns and supports the development of more reliable components and robust design methodologies across the accelerator complex.

Rapid Diagnosis of Vacuum Leak in LHC

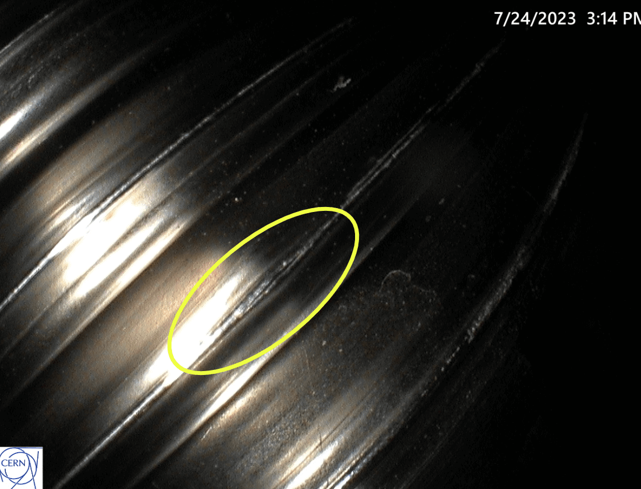

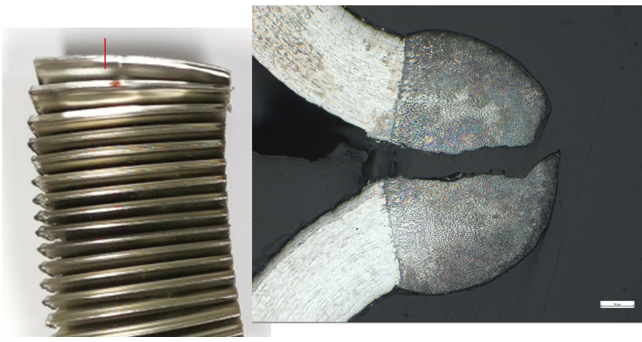

In July 2023, an electrical disturbance caused several superconducting magnets in the LHCb interaction region to quench, resulting in a vacuum leak in the inner triplet magnets and threatening to interrupt the LHC physics program.

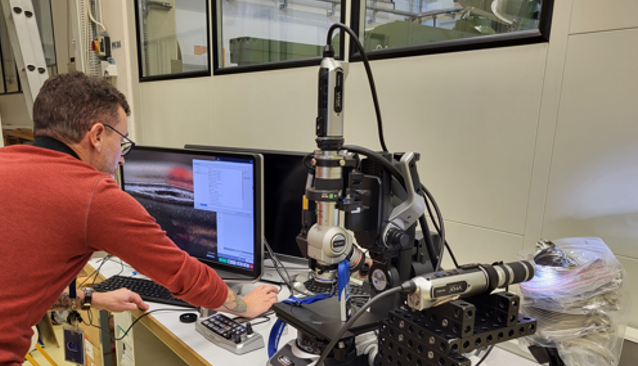

Within days, our experts used on-site visual inspection and industrial radiography to localize the failure, identified in the form of a 2 mm-long crack in the corrugation of a vacuum bellow to the left of Point 8.

Subsequent microscopic analyses determined the root cause of the failure, enabling a rapid repair and supporting the consolidation plan approved for Long Shutdown, which will ensure safer and more reliable operation in future runs.

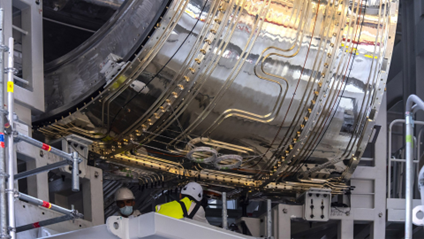

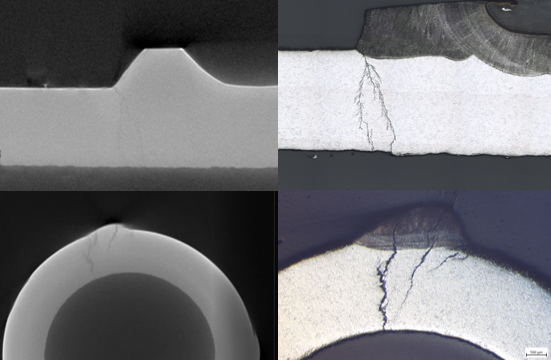

Analysis of the Leakage Events in the Thermal Shield Cooling Pipes of the ITER Magnet System

The ITER Thermal Shields are stainless-steel cooling panels that protect the reactor’s superconducting magnets by reducing heat from warmer components. During installation, three helium leaks were discovered in the cooling pipes. A detailed investigation using advanced imaging techniques revealed crack formations and corrosion residues containing chlorine. The failures were traced to stress corrosion cracking caused by halide residues from the silver-coating process combined with stresses from welding the pipes to the plates. The study outlines the findings, lessons learned, and the repair and replacement strategies planned to resolve the issue.

FIND OUT MORE

Keen to learn more about our activities?

Find out what the Material, Metrology and NDT Unit can do for you.