Publications

Advanced Materials and Manufacturing for Accelerators and Fusion

We develop, characterize, and qualify structural and functional materials for accelerator and fusion technologies. Recent research focuses on cryogenic mechanical testing, surface engineering, development of low-Z materials, and superconducting solutions.

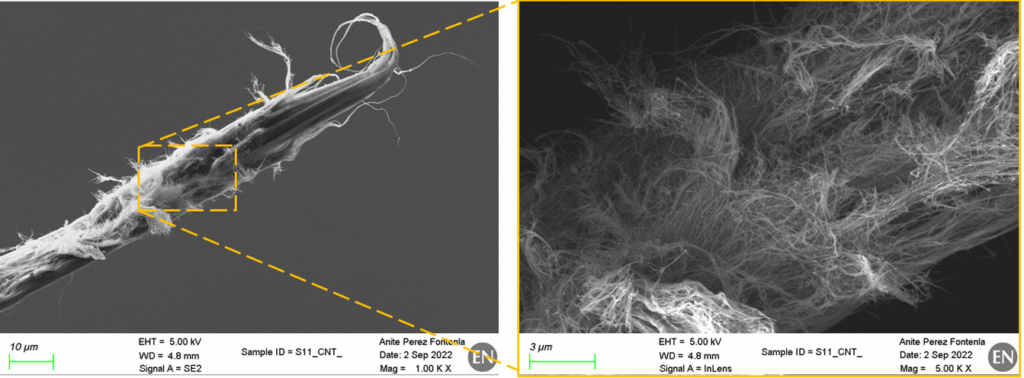

Mechanical characterization of yarns made from carbon nanotubes for the instrumentation of particle beams at CERN

CERN uses extremely thin copper-coated carbon fibers as “wires” in devices that scan and measure the shape of particle beams. These wires are now operating close to their physical limits, and to meet the demands of CERN’s next-generation accelerators, a new design is needed. A promising alternative to the current fibers is the use of lightweight yarns made from spun carbon nanotubes (CNT yarns), which could offer greater strength and stability.

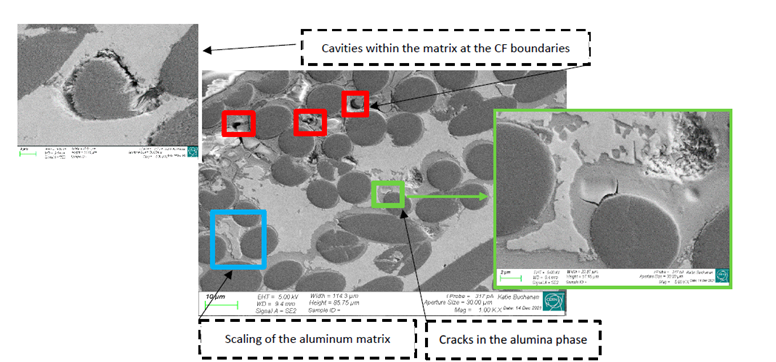

at the boundary between the matrix and the Cfs, locally filled with corrosion residues

The CMS experiment at CERN requires lightweight, highly stable components to support and cool silicon sensors in its new Outer Tracker detector. Aluminium–carbon fibre (Al/Cf) composites are ideal for this role, but they must be manufactured reliably and remain dimensionally stable under cold operating conditions and environmental stress. This study shows that the chosen manufacturing approach plays a pivotal role in the final performance of these components when exposed to the extreme conditions of service.

Material Performance in Demanding Conditions

Is our goal to better understand how components behave in the real operation conditions in the accelerator (radiation effects, vacuum properties, mechanical behaviour at high or low temperatures, fatigue, corrosion resistance, beam interaction…)

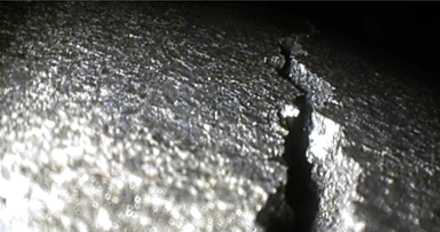

The beam dumps of the LHC are essential safety devices that absorb the particle beams when the machine stops, especially during unexpected situations. As the LHC has increased its beam energy over the years—and will push even further with the upcoming High-Luminosity upgrade—these dumps face much harsher conditions. To make sure they can keep working safely, scientists needed to inspect how the materials inside them had actually been affected by real beam impacts.

Dismantling the existing beam dumps, is a difficult task because of their large size, complex construction, and the radiation they had accumulated. Special tools, techniques, and facilities had to be created to safely remove and examine the internal components.

Radio-frequency quadrupoles (RFQs) are essential components in many particle accelerators, but they can be damaged by strong electric fields and by hydrogen ion beams, which create tiny surface blisters and reduce efficiency. Ongoing investigations are exploring whether advanced metals could outperform the copper traditionally used. These tests include various copper alloys, stainless steel, titanium alloy, niobium, and tantalum, all of which were exposed to hydrogen irradiation and then subjected to high electric fields. Researchers examined how the surfaces changed and how much electric field each material could withstand before breaking down.

Component Integrity and Failure analysis:

We provide in-depth evaluations of components integrity and material failures that help to avoid critical breakdowns and supports the development of more reliable components and robust design methodologies across the accelerator complex.

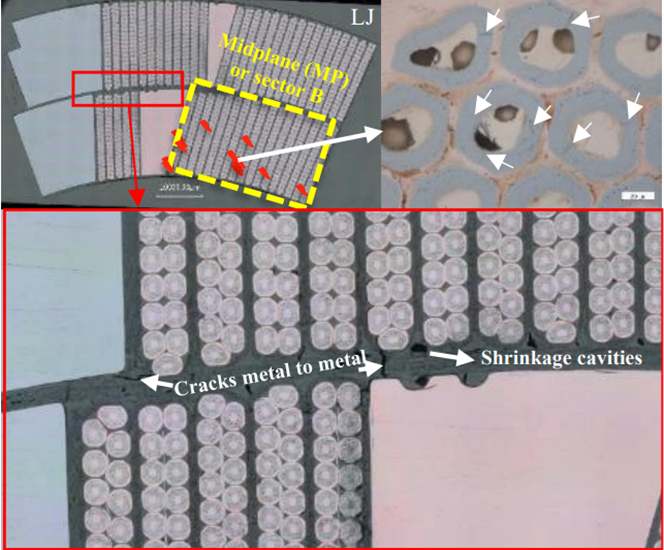

A Metallurgical Inspection Method to Assess the Damage in Performance-Limiting Nb3Sn Accelerator Magnet Coil

The High-Luminosity upgrade of the LHC requires new, extremely powerful magnets made from Nb₃Sn superconducting material. These magnets must bend and focus the particle beams more strongly than ever before, but their fabrication is challenging, even microscopic defects in the coils can trigger “quenches,” sudden losses of superconductivity that limit performance. To better identify and understand these defects, a new inspection method combining advanced non-destructive and destructive techniques has been developed. This approach allows engineers to closely examine the internal structure of Nb₃Sn coils and investigate the root causes of performance-limiting events.

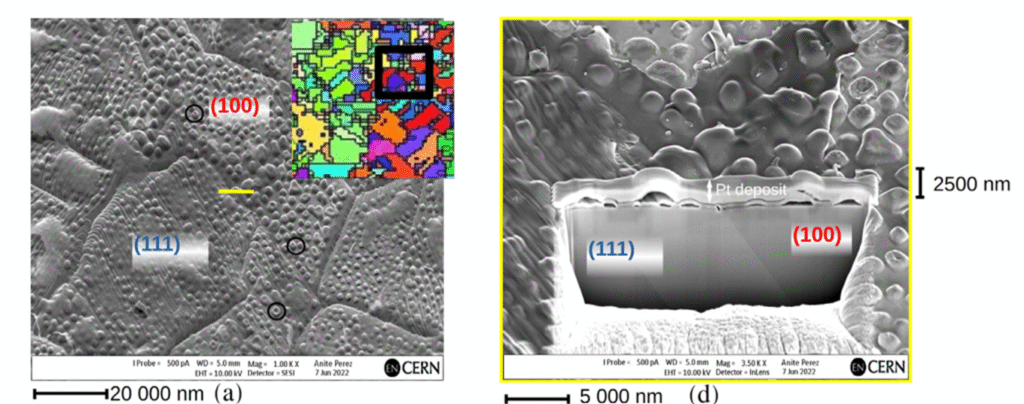

Development and characterisation of advanced coatings for high energy physics applications

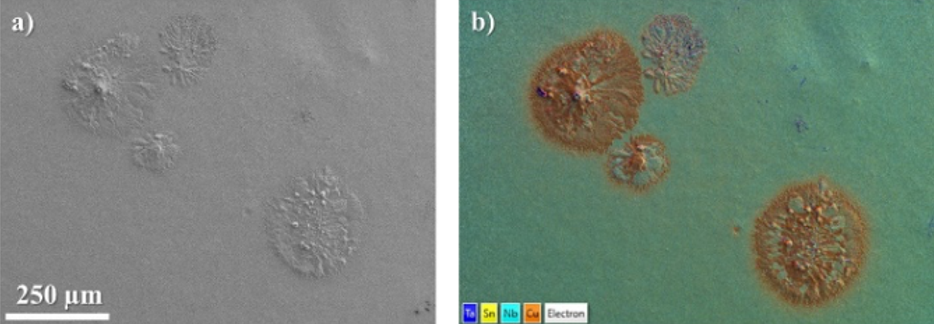

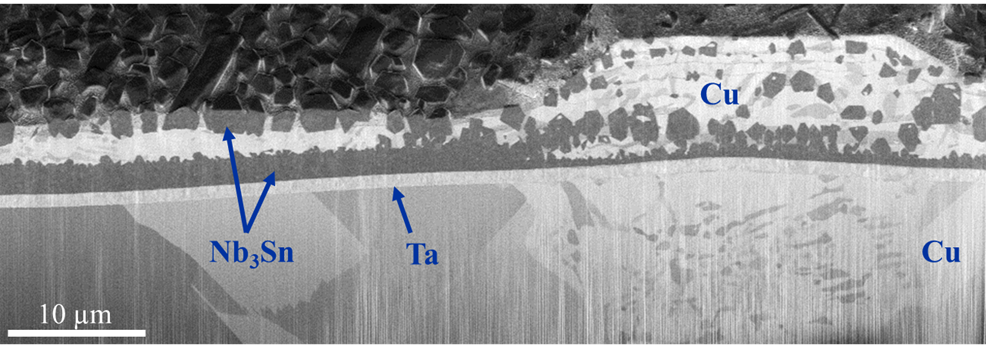

The Future Circular Collider (FCC) aims to advance particle-accelerator technology well beyond today’s capabilities, which demands highly efficient Superconducting Radio Frequency (SRF) cavities to accelerate particle beams. CERN has traditionally used niobium coatings on copper cavities, but this approach can lose performance at high fields. As a result, new materials such as Nb₃Sn, are now being studied, along with improved coating methodology like High Power Impulse Magnetron Sputtering (HiPIMS). During this development, researchers observed that under certain coating conditions, the surface of the Nb₃Sn film showed tiny copper “islands”.

View all our publications here.

FIND OUT MORE

Keen to learn more about our activities?

Find out what the Material, Metrology and NDT Unit can do for you.