Our Collaborations

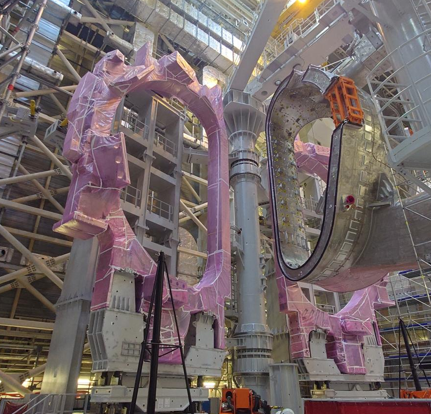

Big Science: ITER Project

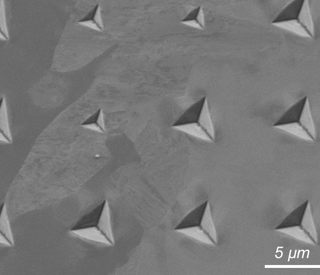

The ITER Project relies on components of unprecedented size, strength, and precision, where even microscopic defects can compromise performance or safety. Since the launch of a major cooperation agreement in 2009, the EN-MME-MM section has served as ITER’s reference laboratory for materials expertise, cryogenic testing, advanced non-destructive evaluation and high-resolution microscopy to detect tiny flaws—true “infinitesimal needles in a haystack”—in critical parts to be installed in this innovative fusion machine.

This long-term partnership not only secures ITER’s demanding quality and safety requirements but also drives progress in cryogenic mechanical testing and the development of robust materials for future accelerator applications and advanced reactor technologies, supported through additional agreements via CERN’s Knowledge Transfer group.

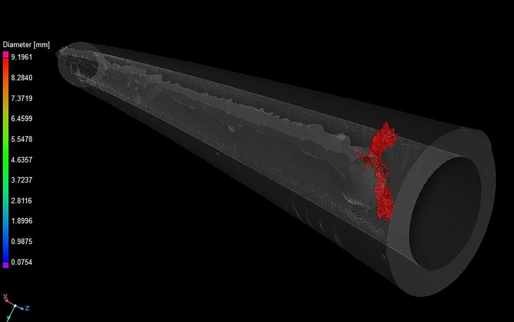

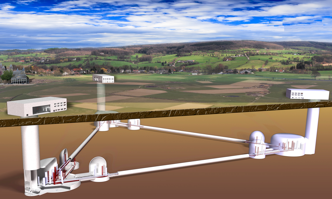

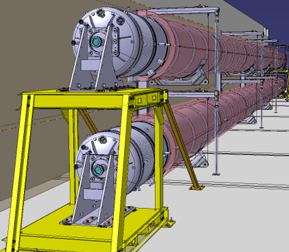

Big science collaboration: Einstein Telescope Project vacuum system

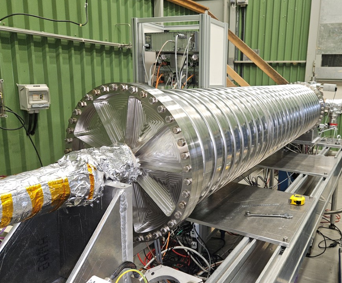

Since 2022, EN-MME has been collaborating with TE-VSC, other researching centres and the industry to develop suitable, cost-effective solutions to manufacture and integrate the largest vacuum system ever built.

This project brings together a truly multidisciplinary team, with essential contributions from the design office, materials experts, metrology and non-destructive testing specialists, the mechanical workshop, assembly and metal-forming teams, as well as CERN’s technical subcontracting service.

The team is currently installing and testing a 50-meter-long pilot sector at CERN. These tests will validate the proposed technical solutions before they are deployed across the full 120-kilometer system.

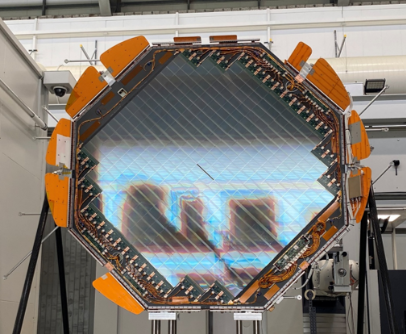

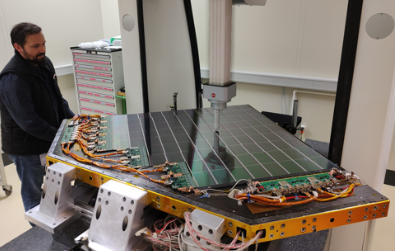

Precision Metrology for the AMS Detector Upgrade

For the upcoming upgrade of the Alpha Magnetic Spectrometer (AMS) aboard the International Space Station, metrology plays a critical role in ensuring the precise alignment of all detector components. The CERN Metrology Laboratory developed dedicated procedures to position each electronic sensor with micrometric accuracy and to verify the flatness of every Quarter Layer (QL) during assembly.

A custom optical measurement system, combining a high-precision camera and a chromatic confocal sensor integrated into a CNC machine, was designed in-house to achieve the required accuracy — a unique solution when no existing coordinate measuring system could meet the mission’s stringent specifications.

Knowledge transfer: Testing steel to harness the energy of tomorrow

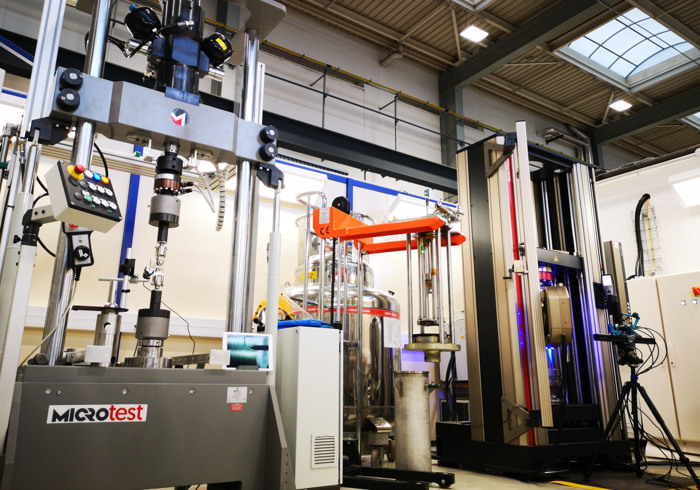

Via knowledge transfer (KT) collaborations, our section has partnered with Rolf Kind GmbH, a German company specialized in high-alloy stainless steel forgings, to identify materials capable of meeting the extreme demands of next-generation fusion power plants.

Working with the EN-MME Materials, Metrology and Non-Destructive Testing section, the steels were tested at cryogenic temperatures down to 4 K (-269 °C) to assess their mechanical performance.

This collaboration combines industrial expertise and CERN’s advanced cryogenic testing capabilities, helping to overcome a key challenge on the road to harnessing fusion energy.

Knowledge transfer: Testing steel to harness the energy of tomorrow

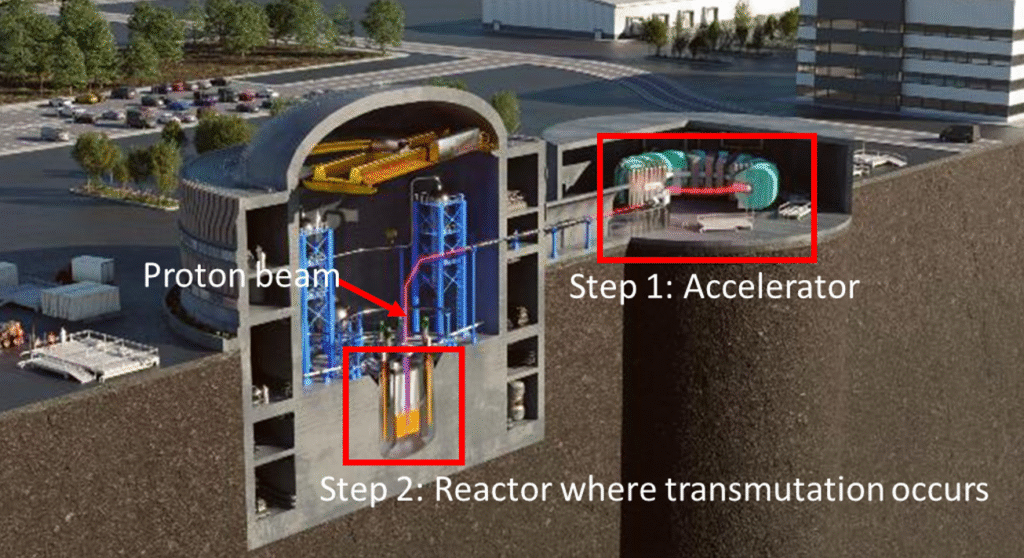

We support Transmutex in advancing their innovative reactor technology by providing expertise in materials behavior under extreme conditions. We support Transmutex in advancing their innovative reactor technology by providing expertise in materials behavior under extreme conditions.

FIND OUT MORE

Keen to learn more about our activities?

Find out what the Material, Metrology and NDT Unit can do for you.