Non-Destructive Testing

From quality to safety, insight without damage

Ensuring that materials and joints meet CERN’s requirements through advanced inspection methods that preserve integrity

Non-destructive and highly instructive!

Certified experts for versatile support

Our personnel is trained and ISO 9712 certified across multiple techniques. This versatility allows us to support you throughout the entire manufacturing chain — from conception and technical specifications to fabrication follow-up and developments— ensuring inspectability and reliability at every step

01

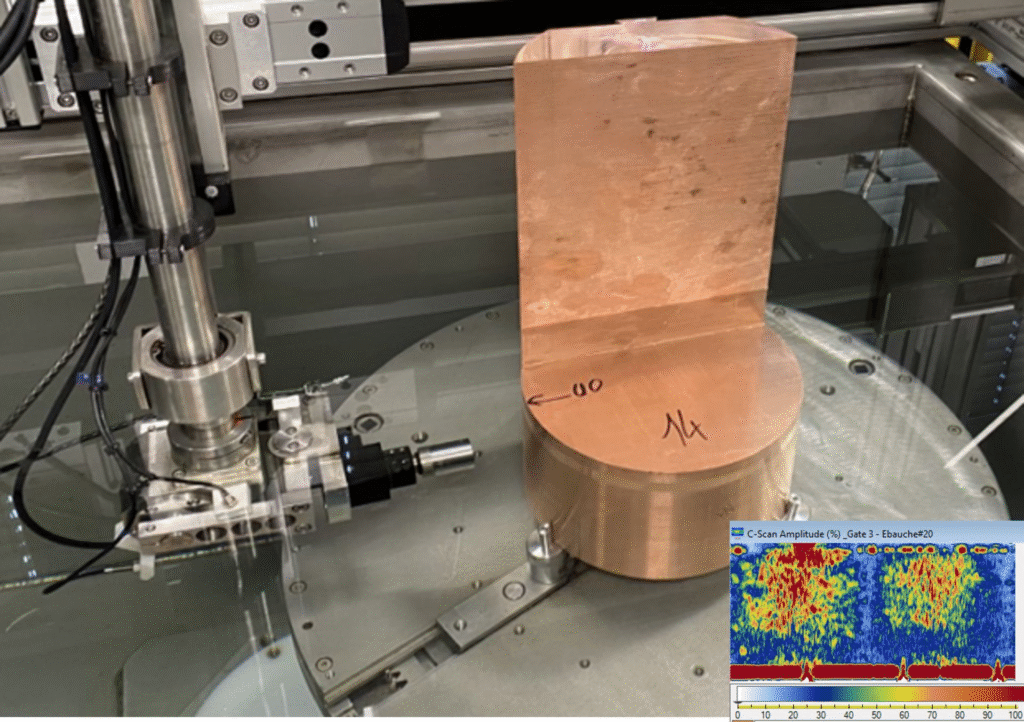

Verifying every critical delivery

We perform reception inspections of CERN’s most critical raw materials and products, here or at providers’ premises, while also supporting the qualification of new providers and manufacturing developments.

02

Trusted assemblies

Specialized in testing any kind of joints including welded and brazed, we validate them for the most demanding applications (UHV, RF, cryogenics…), safeguarding leak tightness and structural integrity in critical environments, even under extreme pressure, vibration, and thermal cycling.

03

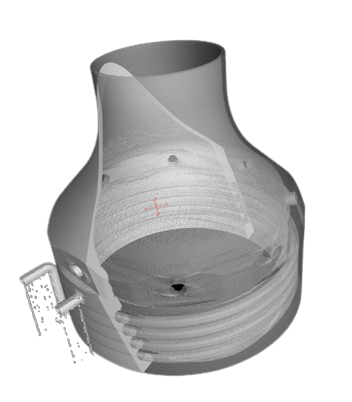

3D insights with CT

We reveal internal structures and flaws without damage. With resolutions down to micrometres, our computed tomograph delivers precise 3D reconstructions and CAD comparisons.

04

Timely support

We adapt to programmed campaigns and maintenances, as well as urgent interventions, ensuring inspection capacity for developments, constructions, failure analysis, troubleshooting, upgrades, documentation, and continuous operational improvements.

05

In safe hands

Our experts manage the entire process, from laboratory and bunker inspections to on-site interventions at CERN, complying with international standards and CERN safety rules.

FIND OUT MORE

Keen to learn more about our activities?

Find out what the Material, Metrology and NDT Unit can do for you.